Moltex Energy, CNL explore innovative waste conversion tech for SSR

United-Kingdom/Canada-based Moltex Energy has begun the latest phase in its drive to develop its waste burner Stable Salt Reactor (SSR) after an agreement with Canadian Nuclear Laboratories (CNL) in April.

Related Articles

The program supports the second and third phases of Moltex Energy’s Oxide Nuclear Waste Reduction Demonstration (ONWARD) project which aims to explore the commercial viability of the innovative WAste to Stable Salts (WATSS) technology.

WATSS takes spent Canada Deuterium Uranium (CANDU) fuel bundles, recovers fissile, fissionable and fertile materials and converts it into fuel for molten salt reactors.

The project, funded through CNL’s Canadian Nuclear Research Initiative (CNRI), is for one year.

“This agreement is very important because to carry out fuel development, Canadian Nuclear Laboratories have the best facilities and expertise in Canada and some of the best in the world,” CEO for North America at Moltex Energy Rory O’Sullivan tells Nuclear Energy Insider.

In July last year, the company signed a Memorandum of Understanding with the utility New Brunswick Power and the New Brunswick government to move toward plans to build, own and operate a 300 MWe SSR-W300 reactor. The reactor design is currently running through the first phase of its development, a Vendor Design Review with the Canadian nuclear regulator.

Moltex Energy believes its SSR is highly competitive against other molten salt reactors due to the simplified design which places molten salt fuel in fuel rods like conventional assemblies rather than pumping fuel salts around valves and heat exchanges.

The group estimates the overnight capital cost of its SSR at $1.95/W based on a 1 GW plant, which compares to Energy Information Administration estimates for coal-fired generation of$3.25/W, gas fired generation of around $1/W and large scale nuclear of $5.5/W.

The company has said the Levelized Cost of Energy (LCOE) of its SSR is estimated at $44.64/MWh for a 1GW plant based on highly-conservative estimates for Operations and Maintenance (O&M), far below the EIA’s cost projections for new coal and gas-fired units, with LCOEs of $95/MWh and $75/MWh respectively.

If everything goes to plan, Moltex Energy hopes to have a fully working, licensed reactor by 2030.

Single-step pyroprocessing

WATSS includes a newly developed single-step pyroprocessing technique for the continuous electro-reduction of Uranium Dioxide spent fuel, Ali Siddiqui, Program Manager of Advanced Fuels at CNL, tells Nuclear Energy Insider.

“Moltex pyroprocessing technique overcomes problems observed in processes developed in the past. Because WATSS is based on a pyroprocessing technique, the whole process is compact and doesn’t have the problems of effluent management incumbent in the dissolution-based techniques,” Siddiqui says.

With more than 2.8 million used nuclear fuel bundles in Canada and 90,000 added each year, the commercialization of the WATSS process will allow for the conversion of expensive-to-handle waste.

“If this technology is successful, it will help a lot to close the nuclear fuel cycle. It will take the spent uranium dioxide fuel and convert it into stable salt that will contain U, Pu (neptunium) and minor actinides,” Siddiqui says.

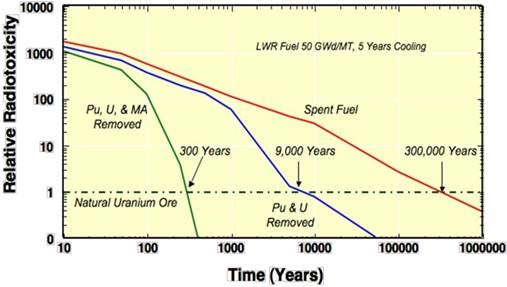

(Sarah Wilder, Nov 2009, The Risk of Nuclear Power: Weighing the Safety and Proliferation Concerns Associated with Nuclear Energy against the Threat of a Changing Climate and Energy Security. 2009 AIChE Annual Meeting)

Since that stable salt is to be used in the Moltex Energy reactor and, most likely, other molten salt reactors, which operate in the fast spectrum, long-lived actinides will be transmuted into non-radioactive, or short lived, materials.

Once the technology is shown to work, it will provide an alternative to spent fuel storage in the Deep Geological Repository (DGR), Siddiqui says.

“Consequently, it will certainly provide an opportunity to reduce the cost, volume and toxicity of waste that needs to go into a DGR, reducing highly radioactive legacy waste for future generations,” he says.

Fuel testing

Moltex Energy, the University of New Brunswick (UNB) and CNL will design, build and optimise a fuel testing apparatus at the UNB’s Centre for Nuclear Energy Research, with CNL supporting Moltex Energy on specialised equipment preparation, installation and commissioning.

“From a licence perspective, the ability to be able to use the waste is huge, because that’s the biggest issue with nuclear power,” O’Sullivan says.

“The CNL is the only facility in Canada which has the right equipment and skills to be able to handle and do experiments on real, radioactive fuel.”

The conversion of CANDU to SSR fuel is much cheaper than other processes because the necessary separation doesn’t take out much of the active fission products, which can be expensive, complicated and present a proliferation risk as the materials can be diverted in to weapon use, he says.

“Since we don’t have to do any of the complicated separation, we don’t have a risk of creating materials that can be used for weapons purposes and, importantly, is it makes it cheaper.”

Exactly how much separation of the spent fuel can be achieved remains undetermined, a factor that will have an impact on the final facility, and Moltex Energy says the CNL testing can help clear that up.

The main challenges are technical, notes Siddiqui. Testing will show if the Moltex Energy process works as expected and solves issues previously observed, will find the optimal process parameters and will help determine if the materials selected are correct and can withstand the harsh process conditions for a long period of time.

And, of course, the cost.

“This process has to prove that it is more economically viable than liquid-based reprocessing and also than fuel storage in the DGR,” Siddiqui says.

By Paul Day