AI gains ground in nuclear industry

Nuclear power plants for decades relied on analogue systems and human operators, but increasingly sophisticated artificial intelligence applications are helping streamline operations.

Related Articles

A nuclear power plant is a complex system with instrumentation that, if it fails, can adversely affect performance and safety. While many modern plants have been digitalized, they still rely on traditional and, often, inefficient operational and control methods.

As AI and machine learning (AI/ML) programs become more sophisticated, researchers are seeing the potential use of the technology for a range of applications, including equipment prognostics, data sorting and management, autonomous control and operation, digital twin applications, and work planning and management.

“Historically speaking, the nuclear power industry has been very reliant on people and because of that, over time, the industry has become more expensive compared to those industries that have adopted automation. We realized in the late 2000s that the industry needs to evolve and transform the way it does business,” says Senior Research and Development Scientist at the Idaho National Laboratory (INL) Ahmad Al Rashdan.

Human operators will always be at the heart of a nuclear power station, especially for operations relating to the safety of the plant, but there are many jobs that machines can do better.

“A lot of the activities done at nuclear power plants relate to the deep analysis of forms of data. We analyze texts, we analyze images, we look at census data. It's not just simple automation. In this case, automation means something more intelligent, more capable. And that's where AI comes in.”

Sorting the data

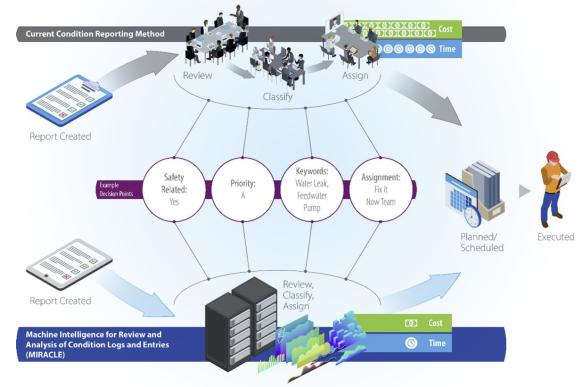

The Machine Intelligence for Review and Analysis of Condition Logs and Entries (MIRACLE) tool is just one of more than a dozen AI/ML applications at INL that Al Rashdan and his team are working on.

The nuclear industry documents issues that come up at plants in condition reports, and experienced staff members spend tens of hours reviewing these reports – which log anything from broken office chairs to leaks to broken piping – sorting the data to assess the issues’ impact and priority and deciding what actions need to be taken.

The process costs hundreds of millions of dollars a year and its manual and subjective nature means errors can be made or misdiagnosed.

MIRACLE concentrates on review time, paperwork, and meetings performed by the humans

(Click to enlarge)

Source: Idaho National Laboratory

MIRACLE automates condition report handling by reading through tens to hundreds of table fields, including free-form fields, sifting through text, and evaluating it against what it has learned from the training sets, says Al Rashdan.

The system is a mix of ChatGPT-type language processors and multiple custom-designed AI neural networks, and it can classify reports in order of importance as well as perform unsupervised learning without labels.

“The reason the systems are so powerful is because we have not, as humans, been good at enabling things in the past and now we have a machine that can do it much more systematically, much more robustly,” he says.

“We tested it against humans and the machine outperformed the human every time.”

In the loop

Digitalization company NextAxiom, as part of a cooperative research agreement with the Department of Energy’s (DOE’s) Light Water Reactor Sustainability (LWRS) program and leading nuclear utilities, has been combining the latest advances in domain-specific AI with plant information, business processes, and procedures to create a Virtual Resource Management Framework (VRMF).

This framework will integrate many of the AI/ML research initiatives within the LWRS Program, according to Craig Primer, who directs plant modernization research teams in digital and information modernization at INL.

These include remote monitoring, anomaly detection, computer vision, and NLP applications as well as leveraging NextAxiom’s expertise in software design and development such as computer-guided work and silo-free applications.

AI could eventually be used directly as a control, like brakes in a car, says Primer, but for now the nuclear industry uses AI to alert operators to conditions, similar to a car’s ‘Forward Collision Warning’ that detects a potential collision with a vehicle ahead and provides a warning to the driver.

The AI systems will continue to have a human overseer for the foreseeable future, will not be used at all for safety related functions and don’t impact licensing use.

Primer’s team is regularly sharing research results with the U.S. nuclear regulator which, alongside regulators from Britain and Canada, are working on a trilateral effort to develop guidance in this area.

“Across all industries, we need to set limits on the types of controls we allow AI to manage autonomously. So, for things that could have serious consequence, we should be aware of what those are, and we should make sure we have humans in the loop. AI does not make those kinds of decisions,” says Primer.

AI islands

As researchers train AI systems to sort power plant data and recognize plant anomalies that could avoid shutdowns and enable early replacement of worn equipment, the systems will soon be required to do more complex tasks.

The deployment of very small, advanced reactors, or microreactors, in far off, isolated areas such as mines and cut-off communities, will likely be enabled by the development of self-driving systems run by AI.

However, for the moment, the full potential of AI technology for the nuclear industry is yet to be fully defined.

“We're at the beginning of this process. We have these islands of AI use, but they're limited. There's no framework, no interconnectivity. And so, we want to develop this framework that will manage and integrate more and more advanced AI processes,” says Primer.

By Paul Day