Angeli Mehta reports on the companies that are using fourth-generation technologies to cut greenhouse gas emissions on roads, the seas and in the air

The use of artificial intelligence will be critical to delivering truly autonomous vehicles and seamlessly integrated transport in cities one day. But we don’t have to wait until tomorrow to reap the benefits of fourth-generation technologies such as AI and machine learning.

They are already being used in a host of transport applications, cutting CO2 emissions on the roads and in even more challenging sectors such as shipping and air transport.

Road transport

In a handful of US cities, machine learning is being employed to improve vehicle flow. In Pittsburgh this has reduced engine idling by 40%, delivering an estimated 20% cut in carbon emissions.

The Scalable Urban Traffic Control (Surtrac) system – developed by scientists at Carnegie Mellon University (CMU) – enables each junction to set traffic light sequencing according to real-time information on traffic volumes, collected from cameras and radar. Data is shared with computers at nearby intersections, to predict the flow of vehicles.

The university’s scientists are now developing a computer vision system to try to quantify pollution levels.

Machine learning means we’re always refining, always improving

Pittsburgh has funding to roll the Surtrac system out across 150 intersections over the next year.

“Machine learning means we’re always refining, always improving,” says Karen Lightman, executive director of Carnegie Mellon’s Metro21: Smart Cities Institute. Each new iteration allows policymakers to give priority to distinct subsets of city users, she explains.

Early on they learned that while traffic flowed, pedestrians got stuck waiting to cross busy roads. Now cross-walk signals are tied into the traffic system, and it can even learn that some pedestrians will need longer to cross a road than others. The next step is to optimise the system for emergency vehicles and buses.

Sharing data is key, as is addressing the privacy challenges thrown up by Pittsburgh’s high-resolution camera systems.

IBM’s Green Horizons project uses AI to analyse the data from sensors all over a city to produce kilometre-by-kilometre pollution forecasts up to 72 hours in advance so that authorities can take action, such as warning commuters and closing roads.

The system, initially developed in China and now being piloted in Johannesburg, uses weather, temperature, humidity, wind patterns and traffic levels, alongside measurements of harmful pollutants like nitrous oxide, sulphur dioxide and particulates.

Shipping industry

Shipping emissions account for 2.5% of global greenhouse gas (GHG) emissions and could rise by as much as 250% by 2050 under a business-as-usual scenario, according to the International Maritime Organization (IMO) . Last year it announced a target to reduce shipping emissions by at least 50% by 2050, initially through efficiency measures.

In tandem, it is also trying to cut air pollution: from next January, vessels will have to use fuel oil with a lower sulphur content of 0.5%, compared with the current 3.5%, or to invest in scrubbers.

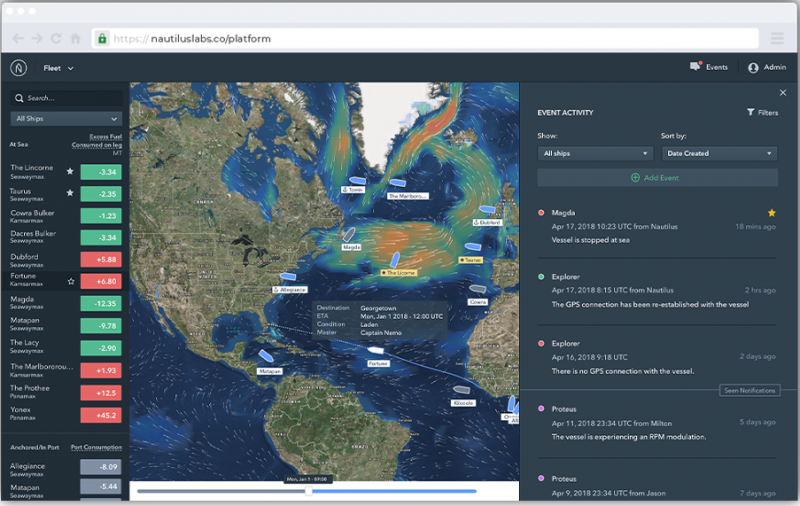

“We’re on the IMO’s 2020 doorstep for sulphur emissions; everyone is uncertain and nervous and expecting higher fuel costs – and keen to keep costs down,” according to Matt Heider, CEO of Nautilus Labs, a New York company that uses AI to help shipping companies achieve greater efficiencies.

Once-a-day reporting masks variations that could impact on a ship’s fuel efficiency, yet it informs judgements worth hundreds of billions of dollars each year

Heider points out that decision-making in shipping is still based on the 200-year-old practice of “noon reporting”, a data sheet prepared each day by the ship’s chief engineer.

Such once-a-day reporting masks variations that could impact on a ship’s fuel efficiency, yet it informs judgements from maintenance to pricing worth hundreds of billions of dollars each year. Continuous monitoring of vessels, and machine learning to provide decision support puts “the human in the loop, equipped to take the best course of action,” he adds.

Heider estimates his company’s system could ultimately deliver a 30% cut in emissions across a fleet.

Today it’s achieving somewhere between 5% and 10% just by eliminating operational inefficiencies like stopping at sea, and running at speeds that unnecessarily use extra fuel.

Weather data enables the crew to plot the optimum speed so as to arrive in port when scheduled, saving thousands of tonnes of fuel across a voyage. In turn, that allows a ship owner to advertise the real efficiency of a ship and get a better price in the market. Having accurate fuel-efficiency data cuts waste further because better decisions can be made on – for example – vessel placement around the globe to minimise distances travelled without a cargo; and routing and speed instructions.

“In the future there is so much room for improvement – radar, computer vision, vibration sensing, and gyroscopes,” says Heider. “A lot of improvement can be achieved just by leveraging data from the sensors that already exist, and then even more can be achieved by newer, better, different sensors that are being developed.”

If we wait for the IMO to regulate carbon neutrality in the industry, there won't be any ocean left to regulate

He suggests that shipping has been slow to embrace change, partly because the technology hasn’t been there to enable ship owners to easily assess whether advances like installing new rotor systems or using anti-fouling paint on the hull are having an impact. Nautilus enables them to do that.

"If we wait for the IMO to regulate carbon neutrality in the industry, there won't be any ocean left to regulate,” Heider says. “Companies need to automate decision-making to drive the scale of reduction that the world needs in the time-frame that we need it to happen. And they need the business imperative – and the tools – to do it."

Stena Line, meanwhile, is overseeing the deployment of its own system, supporting officers on the bridge to reduce fuel consumption.

“Sailing efficiently is nothing new. For us it’s been an opportunity because more sensors on ships provide a combination of different data sources,” says Lars Carlsson, head of AI at Stena Line. “[The system] can make more calculations – taking account all the physics around a ship – than a human being can do.”

On top of that data-processing capacity sits machine learning. Carlsson says they’ve already seen a significant impact on fuel consumption since deploying the first vessel last December. The next step is to roll it out across five vessels to assess its wider impact.

Understanding customers – when they show up, for example, impacts on how we load the ship, which in turn impacts on fuel consumption

Stena Line’s model still has room for improvement, and it’s possible there will be seasonal impacts. But it can be retrofitted on older ships, and payback is relatively quick, suggests Carlsson.

He adds that another application of AI is in optimising freight flow in ports. “Understanding customers – when they show up, for example – impacts on how we load the ship, which in turn impacts on fuel consumption.” Stena Line has an overall goal for the whole company to be assisted by AI in 2021.

There’s been widespread speculation that ship owners will try to cheat the system to cut the costs of emitting seven times less sulphur dioxide than now. At present, little can be done to enforce the IMO regulations on the high seas, but it’s a different story coming into port.

Jon Knudsen, founder of engineering company Explicit, has spent six years developing a system now being tested around Europe. Sniffer drones are guided into the plume of smoke coming from a ship’s funnel, to measure the gases being emitted. The on-board software can analyse the plume more or less in real time and send the data back to port authorities, or directly to a European reporting system that will alert EU ports to have a vessel checked out. The system is limited by the range of the drone or helicopter, but Knudsen anticipates that near-satellite technology of the type deployed last month by SpaceX, and longer range drones could address the challenge.

But for now, the technology can ensure ships comply with even lower limits of 0.1% sulphur dioxide (SO2) in port.

Knudsen anticipates an improvement in air quality in coastal cities such as his native Copenhagen, where pollution levels can breach EU thresholds. Nitrous oxides are a particular problem, and while there’s no legislation to punish high NOx production, authorities can use the information to assess the impact of shipping.

AI will create deeper accountability and transparency: that’s the transformational change we hope to drive

If ships don’t use low sulphur fuel, they’ll have to install scrubbers – and that has given rise to concern that crews will simply switch them off at sea. But scrubber usage is meant to be logged during a voyage – a paper print-out can be inspected by port authorities.

Heider suggests that, in time, Nautilus Labs’ technology could be deployed to assess whether the scrubbers provide real value.

He expects AI to create “deeper accountability and transparency: that’s the transformational change we hope to drive.”

Air transport

Stig Patey is a pilot with Norwegian whose role is to find the technologies that will help the airline cut its fuel emissions. It’s the pilot who controls fuel consumption across a flight, and Patey finds some routinely burn more fuel than others.

Norwegian is using a system called SkyBreathe, from Toulouse-based Open Airlines, which uses big data analytics to combine flight data recorder information with weather information – and uniquely gives the pilot the full picture to enable them to review their flight in 3D and learn to operate future flights more efficiently.

“We can also see if it was a weather or air traffic control issue that prevented them from operating most efficiently,” explains Patey. For example: coming out of one European airport, the system enabled him to see that the fuel burn was consistently greater than expected.

It turned out the airport had a complex set of instructions on when wing flaps – which provide extra lift at take-off – should be retracted, leading to pilots holding off until a much higher altitude than necessary to pull them in.

Patey is optimistic that SkyBreathe can deliver a 2% reduction in carbon emissions in the first year

This insight led to flaps being retracted earlier, cutting drag on the plane so less fuel was burnt. Getting clearer instructions would have had benefits not just for Norwegian, but for all airlines using the airport. Patey is optimistic that SkyBreathe can deliver a 2% reduction in carbon emissions in the first year.

Other airlines have reported larger reductions, he adds, but Norwegian already has a modern fuel-efficient fleet.

Its pilots can also see how they fare compared with each other; and how well and how frequently they apply fuel-saving best practice. The system shows the actual conditions the crew encountered so that if, for example, there was ice on the runway, the pilot doesn’t get any credit for putting efficiency ahead of safety.

Two years ago, the airline began a research project, part-funded by the Swedish Energy Agency, to use a system that delivers real-time weather forecasting and temperature data in flight.

Developed by AVTECH Sweden, the system uses data from the UK Met Office’s powerful supercomputers, which take over 200 billion weather observations a day. The crew receives high-resolution weather data just eight minutes into the flight, helping pilots achieve optimum cruising altitudes as well as the most favourable point from which to begin the descent. Hitherto, they’d been using forecasts up to 10 hours old.

The study demonstrated savings of 22kg of fuel per flight. Over a year, that could mean a cut in carbon emissions of 16,000 tonnes. Norwegian is still analysing the impact of AVTECH’s system over the longer term: even if the decrease in fuel burn was achieved on just 10% of flights, that would be an improvement, suggests Patey.

The two companies are now working on optimising the climb phase, which presents a different challenge given varying gradients of temperature and wind speeds as the aircraft ascends.

Angeli Mehta is a former BBC current affairs producer, with a research PhD. She now writes about science, and has a particular interest in the environment and sustainability. @AngeliMehta.

This article is part of the in-depth Tech for Good briefing. See also:

Can AI light the way to smarter energy use

How AB InBev is using blockchain to improve the lives of smallholder famers

Bigger, faster, smarter: What the conservation movement can learn from the tech industry

‘AI can’t be put in the “too difficult” box. Boards have to take risks now

The drive to solve tech’s missing women problem

Speed-mentoring initiative Rebus will help women get a hand up the tech ladder