How COVID-19 quickly left legacy systems behind

A new survey from Reuters Events: Supply Chain shows how supply chain executives need to advance technologies and automation to navigate the volatile waters of the pandemic-ravaged industry

Supply chain planners are fighting an uphill battle, frequently lacking the tools and systems to make informed and coordinated decisions finds a new, global survey of nearly 400 supply chain executives by Reuters Events: Supply Chain.

The survey highlights how there is a desperate need to move beyond legacy systems and institute management and forecasting systems that can work across organisations, especially in the wake of the sudden disruption of COVID-19.

Within the survey a third of respondents reported a significant gap between their plans and their eventual execution, hampered by issues around technology performance, integration, visibility and a lack of flexibility in operations and forecasting capacity.

Despite more powerful and affordable tech, manual systems are still common

COVID-19 showcased the vulnerability of global supply chains, particularly in their agility and reaction times, which were critical factors to creating supply chain success in 2020.

Underlying this struggle, many companies seem to still be reliant on tools, such as spreadsheets, which, though useful, are not specialised to handle logistics operations, especially in high-flow and rapidly changing situations. In the survey 22% said they use Excel to plan operations, making it the most popular tool, but a far lower 15% said that they used transport management systems, which are increasingly vital in modern logistics environments.

Overall, 55% of respondents still use manual processes to make planning decisions, with 28% saying that their entire decision making process is manual and lacks any system support.

This was in stark contrast to the number of respondents using entirely automated systems (just 7%) and 20% using an automated system with planner support.

This technological base helps to explain why just 2% of respondents were completely satisfied with their current planning system compared to 30% who stated that they are unsatisfied with the current state of affairs in their supply chain, showcasing the need for updates in how companies plan their supply chain.

Shockingly, 15% of the respondents stated their systems did not have mobile access, a necessity at present, and even more so in a fluctuating climate.

The storm that couldn’t be forecast

This lack of foundational systems is leading to major problems in forecasting, which was noted as their customers’ biggest challenge by Logistics Service Providers (LSPs), 23% of whom said it came top.

The next biggest challenge was visibility, chosen by 18%, which also feeds into forecasting and planning capacity.

When asked whether customers’ existing logistics’ technology supports efforts to improve planning capabilities, 54% of LSPs said it did not, underlining integration problems.

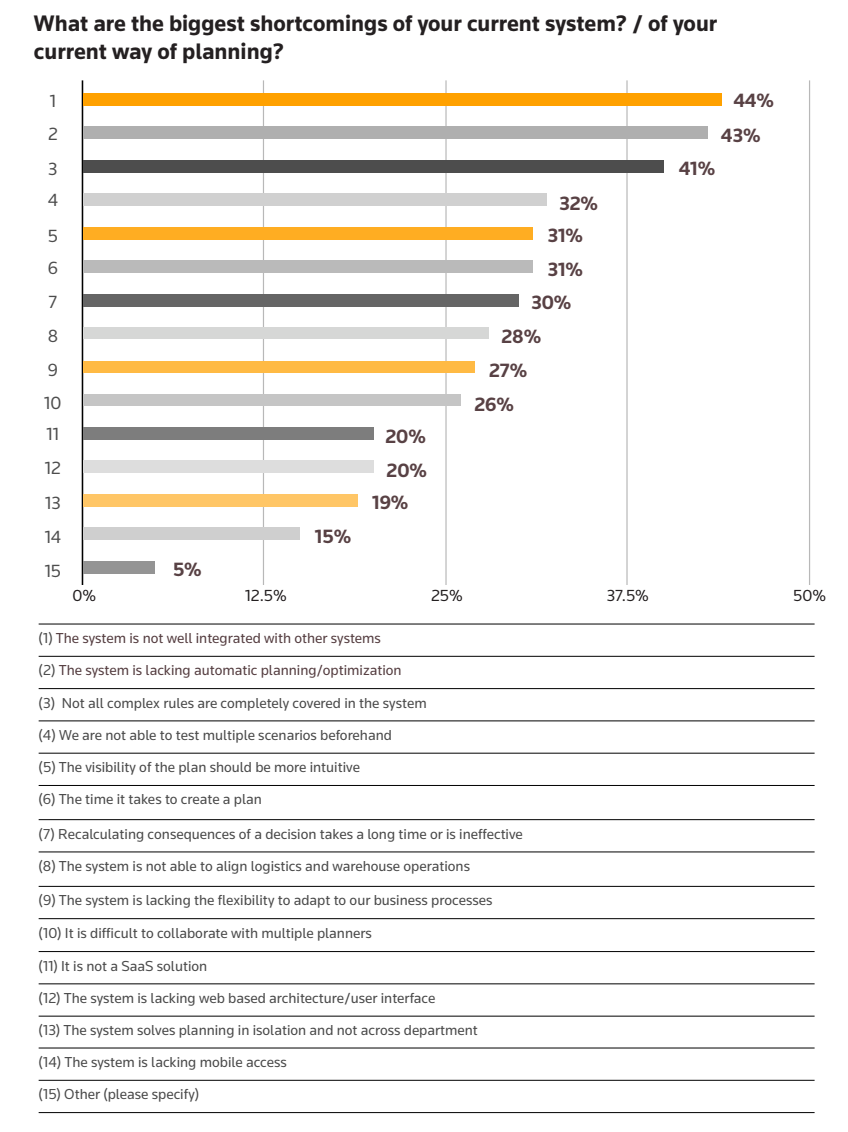

The gaps in approach and systems were all too clear when respondents were asked about the gaps and issues in their planning systems, with the survey finding that:

- 44% think their systems is not well integrated with other systems.

- 43% say their system lacks automation planning/optimisation.

- 41% report that they cannot put in all the complex rules and exceptions they need.

- 32% cannot test multiple scenarios.

- 28% note their system does not link warehouse and logistics operations.

- 26% experience difficulties in collaborating with multiple partners.

The issues were further emphasised by the results that looked at the characteristics of manufacturers’, retailers’ and brands’ supply chain operations. Here, just 27% said that their outbound and inbound operations were integrated, and instead the most popular means of running a supply chain was to allocate full truck loads to a single store, missing out on efficiencies from multiple stops or for maximising return logistics possibilities.

The world has changed fast through 2020, and continues to do so going forward, and accurate planning has never been more important but it is clear that there are still a host of issues to work through. This is especially so as the pandemic will continue in 2021, with questions arising over when areas will reopen fully, and the demand that will be present as and when they do. Though progress has been seen in some automation, and the awareness of the impact of manual processes and inaccurate forecasting, there are significant steps to be made to make use of current technologies, and we can see that this will be a major trend for companies, and their logistics providers, going forward.