Control center owners claim advantage on turbine health

Automation and standardization can generate significant gains in performance and reporting, control center experts told the Wind Operations Dallas Virtual conference.

Related Articles

Amid strong growth outlooks, US wind and solar operators are using central control facilities to maximize profitability.

Many groups are expanding third-party service offerings and centralising performance and dispatch operations to gain economies of scale. Operators can use advanced analytics and growing data pools to improve fleet performance.

Automation is a key way to maximize efficiency from remote operations, Brad Purtell, Director of Services Business Development at Invenergy, told the Reuters Events conference on July 22.

Invenergy, the U.S.' largest privately-held renewable energy operator, currently manages around 10 GW of wind, solar, storage and natural gas facilities, including 2.8 GW owned by third-parties. The group’s control center is in downtown Chicago.

In one example, automation can be used to centralize the monitoring and sorting of turbine reset data across the fleet and help prioritize field visits, Purtell said.

"Those are things that save time, they minimize downtime...In maximising the efficiency of a wind farm, automation is critical," he said.

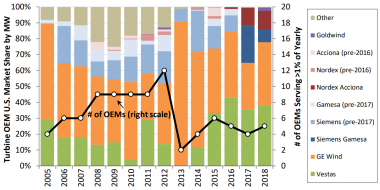

Annual US market share of wind turbine suppliers

(Click image to enlarge)

Source: U.S. Department of Energy's Wind Technologies Market Report (August 2019).

Like many larger wind owners, Invenergy prefers to manage its own assets under a self-perform model and has developed analytics in-house.

Some turbine OEMs have done a "pretty good job" of automating reset functionality, but as an owner-operator, Invenergy is looking to get to the root of the problem, Purtell said.

"We want to understand why that fault is occurring in the first place," he said.

Compliance

A key challenge for fast-growing operators is to keep up-to-date with evolving compliance standards set by the North American Electric Reliability Corporation (NERC) as more wind, solar and storage capacity is connected to the grid.

"The challenge is actually on staying up-to-date with where NERC is thinking they might take the sub-standards," Purtell said.

Operators must ensure the standards are applied consistently across NERC reliability regions and in line with the interpretations of transmission groups, Purtell noted.

"Transient cyber assets is a new one that is coming out,” he said. “That's a little bit more difficult to enforce or understand the intention of.”

Automation can be used to accelerate administrative tasks. Tools can be built directly into supervisory control and data acquisition (SCADA) and computerized maintenance management system (CMMS) platforms, Julien Glover, Control Center Manager at Cypress Creek Renewables, told conference viewers. Cypress Creek operates 3 GW of solar and storage capacity out of its control center in Durham, North Carolina.

"We can ensure not only our NERC compliance, but also our contract compliance with third-party owners," he said.

Standardization of processes allows operators to remain compliant while also staying efficient, Glover said.

"Either if it's through procedures, or training,...standardization is key," he said.

Future proofing

Another challenge for fast-growing operators will be ensuring sufficient staffing levels, Purtell said. Key roles include site technicians, engineers and control center operators and robust training programs are required to efficiently integrate new starters.

"Obviously, you want to automate as much as possible, but you still need additional people, to create that automation, to have that creative way of solving problems," he said.

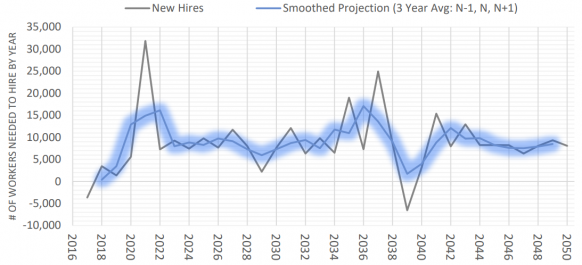

Estimated new hires required in US wind

(Click image to enlarge)

Source: National Renewable Energy Laboratory's 'Wind Energy Workforce in the United States' report, July 2019.

Self-performing operators also face the challenge of integrating multiple technology types and understanding different datasets.

Some OEMs have standardized SCADA platforms to incorporate multiple turbine ages, Purtell said. "But...in terms of pulling the data out and putting it into our performance or control center tools, that's been done on our own."

Operators need to maintain some flexibility, to adapt to evolving technology solutions and supply chains, Glover said.

Standardization must be maximized while changing suppliers or integrating new technologies, he said.

"The key for us is to make sure that everything is as well-documented as possible."

Data access remains a sensitive issue in the highly competitive wind market.

"Condition monitoring systems have really improved on the wind side over the last five years or so. What we struggle with now is getting access to more of that data, and trying to better understand that data," Purtell said.

"Hopefully we can get better access to that and be able to provide better efficiency," he said.

--Robin Sayles