Fatigue assessment studies aim to extend plant lifespans

Component durability within a nuclear power station is tested exhaustively in laboratories, but complimentary studies are looking at how the same materials perform within operational reactors, work that may potentially extend a plant’s lifespan, researchers say.

Related Articles

Laboratory test results over the last 30 years show there may be significant reduction in fatigue life of nuclear power plant (NPP) pressure boundary components when they are tested in light water reactor (LWR) environments rather than when they are tested in air, an effect known as environmentally assisted fatigue (EAF).

The INCEFA-SCALE (INcreasing safety in nuclear power plants by Covering gaps in Environmentally Fatigue Assessment) consortium in charge of the program says this may lead to fatigue assessment parameters beings set more conservatively than necessary.

The $8.1-million five-year INCEFA-SCALE program is mostly funded by the European Union and is a continuation of the INCEFA-PLUS program, which received funding from the Euratom Research & Training program 2014-2018.

The 16-member European team is led by U.S. engineering firm Jacobs.

“Experience from operating nuclear power plants is that component lifetimes almost always, and often significantly, exceed those suggested by laboratory-based predictions,” says Kevin Mottershead, Corrosion and Materials Science Managing Consultant at Jacobs.

Jacobs, operator of the UK’s largest independent nuclear laboratory complex in Birchwood Park, will contribute to multiaxial, thermo-mechanical and complex waveform testing to give a greater insight into the stresses and strains placed on components, the company said in a statement.

The consortium consists of Teknologian Tutkimuskeskus Vtt OY, Paul Scherrer Institut, UJV Rez a.s., Institut de radioprotection et de surete nucleaire, Kauno Technologijos Universitetas, Centro de Investigaciones Energéticas, Medioambientales Y Tecnológicas, Centro De Investigaciones Energéticas, Medioambientales Y Tecnológicas, Universidad De Cantabria, Korea Atomic Energy Research Institute, University of Manchester, Commissariat à l’Énergie Atomique et aux Énergies Alternatives, Joint Research Centre-European Commission, Framatome, Électricité de France, Inesco Ingenieros, and Rolls-Royce Submarines Ltd.

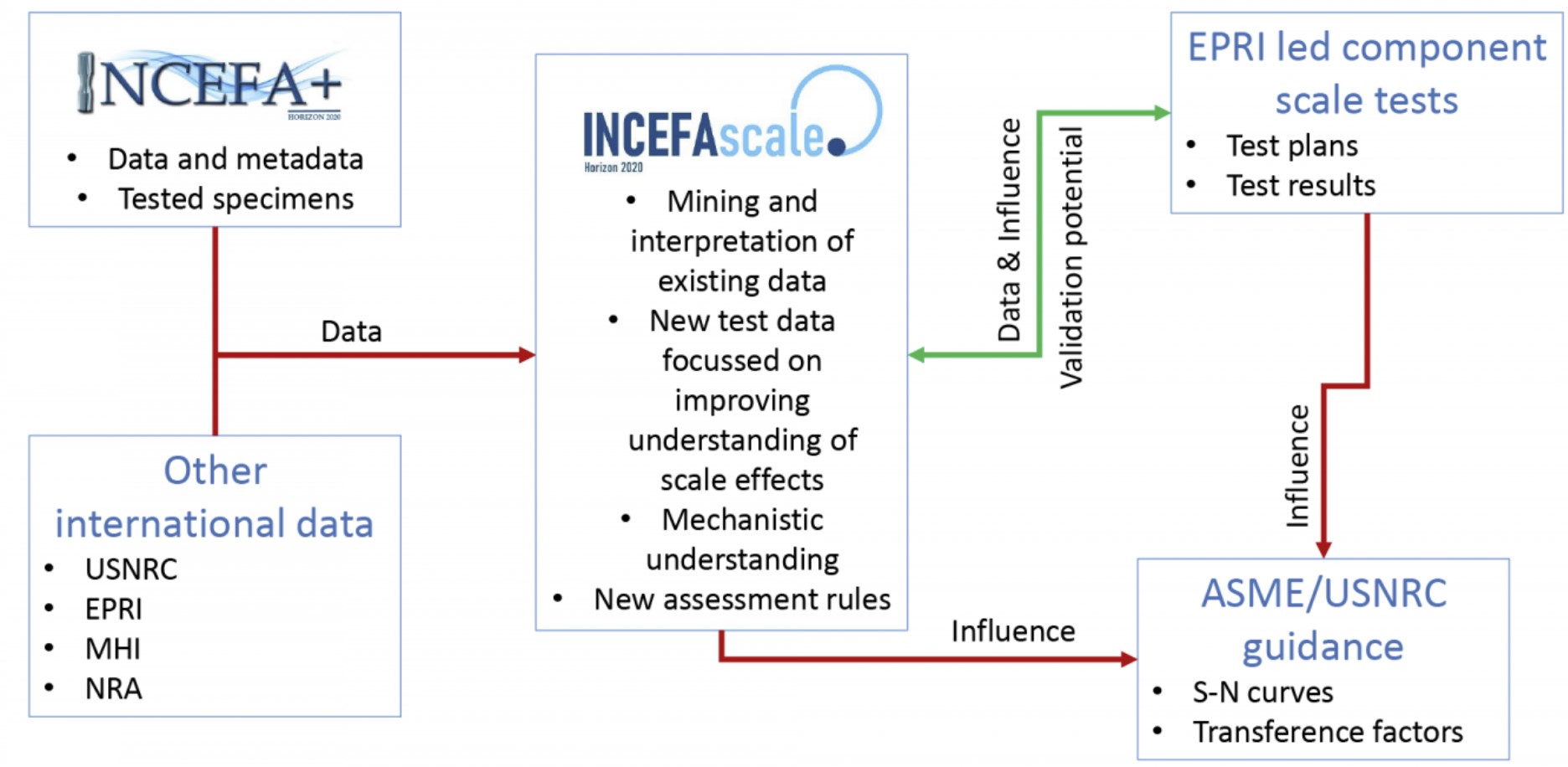

(INCEFA-SCALE external relationships. Source: Jacobs)

(INCEFA-SCALE external relationships. Source: Jacobs)

Complementary studies

The tests aim to complement component scale tests being carried out by the U.S. Electric Power Research Institute (EPRI), which is providing technical consultation to Jacobs and the other members of the INCEFA-SCALE project.

“To date, the worldwide nuclear fleet has not reported any failures of pressure boundary components due to EAF and contends that the design factors used to develop the ASME (American Society of Mechanical Engineers) fatigue design curves adequately accommodate EAF effects,” says Program Manager, International Materials Research, EPRI Nuclear Sector Jean Smith.

“Nevertheless, regulators in the United States and other countries require plants applying for operating license extensions and new plants to perform EAF calculations for nuclear power plant pressure boundary components.”

The INCEFA project, the EPRI materials program, and ASME aim to understand the mechanism behind EAF to further refine fatigue life calculations of NPP pressure boundary components, reconcile the observed differences between EAF calculation results and the lack of observed failures in NPP pressure boundary components and provide the technical bases for improved EAF assessment methodologies.

Continuing research

Around a year and a half after the INCEFA-PLUS project – which ran from July 2015 to October 2020 and published its final conclusions at ASME PVP2020 – was due to finish, it was apparent that the study could successfully underpin improvements in assessment methodologies in Europe and the United States.

“These approaches are similar in that they each endeavour to determine how much environmental penalty is already included in calculated fatigue life before the application of the latest USNRC CR-6909 defined penalty factor for environment. Supporting the validation of these approaches was anticipated to be extremely valuable,” says Mottershead.

It was also accepted that a significant uncertainty affecting assessment reliability would remain due, partly, to the differences between simple uniaxial laboratory test specimen geometries and the complex geometries and loadings seen by real plant components.

“Indeed, this uncertainty is considered so important that an EPRI led consortium was already embarked on setting up demonstration EAF tests on full-scale plant geometries,” he says.

The full-scale tests were expected to deliver data that was useful, though it was limited due the large amount of data needed and its applicability to all foreseen plant geometries and conditions.

To keep the ball rolling on studies that had proved essential, but limited, the INCEFA-SCALE project kicked-off just as INCEFA-PLUS ended.

The INCEFA-SCALE consortium will spend the first year examining the existing data closely to consider its usefulness and evaluate where the data gaps are.

“What will be new for INCEFA-SCALE will be the focus on mechanisms, which is necessary to facilitate extrapolation of the EPRI led test data to all anticipated plant geometries and conditions. Traditionally, EAF has mostly been tackled empirically (including in INCEFA-PLUS), the mechanistic understanding approach is therefore innovative in this subject area,” says Mottershead.

Extending plant lifespans

Mottershead explains that fatigue analyses are time limited aging analyses (TLLA) that, in practise, mean the License Renewal of the power station in question is subject to prove this degradation mechanism is below the limit during the operation and for extended or long term operation.

“Better data will remove or reduce uncertainties and over conservatism concerning component performance and lifetime, which can lead to premature shutdown of safe and economically viable Nuclear Power Stations,” he says.

Further test results and laboratory data will build on the growing information necessary to provide detailed understanding of the EAF mechanism, with particular importance placed on understanding the influence of plant operating conditions such as water chemistry and flexible power operations on fatigue life, Smith says.

“Increased confidence in the aging management, license extension, and new construction fatigue aging management strategies will lead to optimized scope and frequencies of required component inspections and replacements of assets, and potentially lead to significantly lower costs for managing EAF in nuclear power plant pressure boundary components,” she says.

By Paul Day