AI finds a place in nuclear O&M

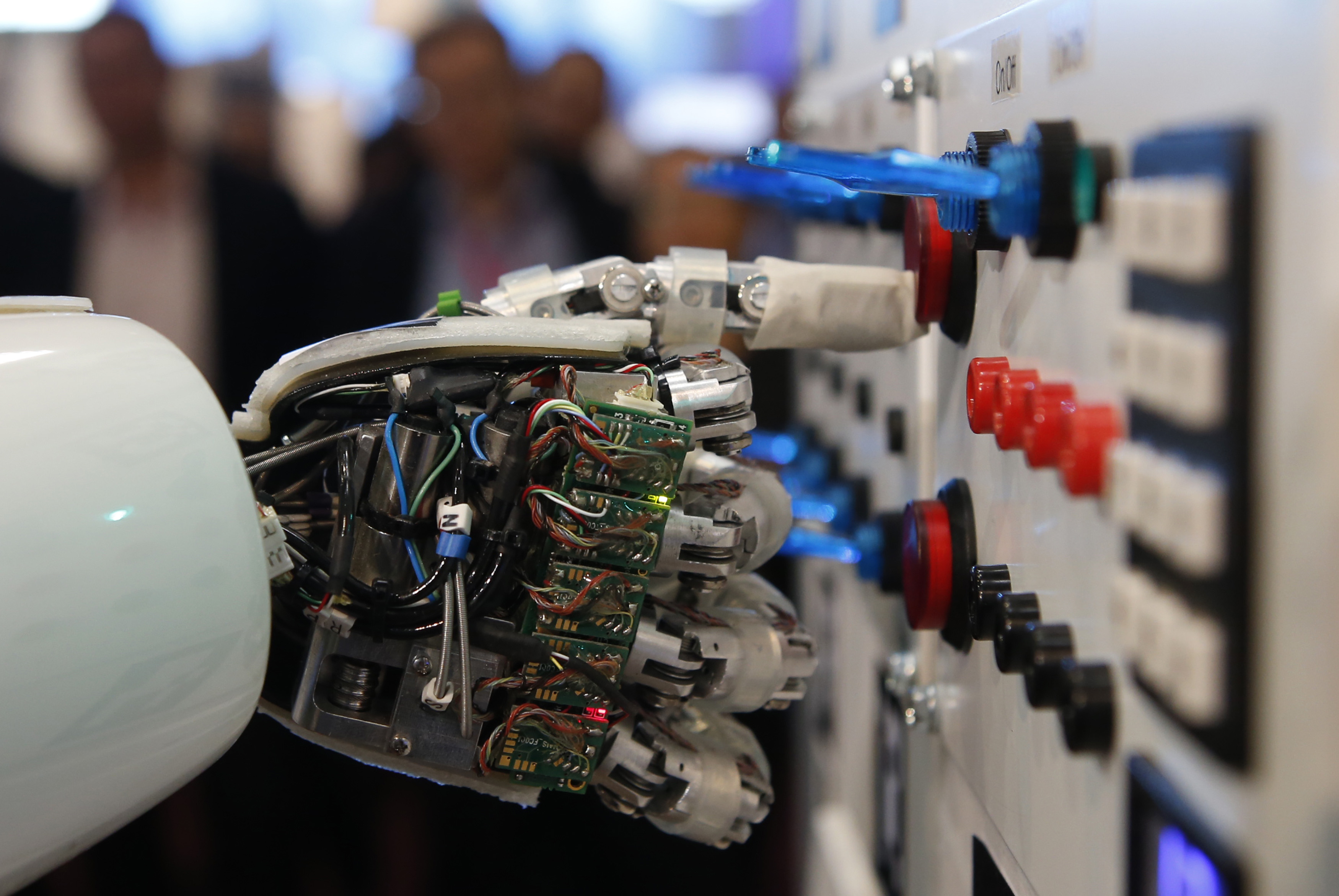

The use of artificial intelligence and machine learning (AI/ML) can make nuclear power plants cheaper to operate and maintain, and more flexible as part of a mixed generation grid, but the technology has its limits, say experts.

Related Articles

AI/ML has already shown itself to be transformative in other industries and its application is being closely studied by nuclear companies which want to incorporate the technology into their advanced reactors designs, but there are areas, such as in the control room, where the technology is neither ready nor desirable.

“There’s some low hanging fruit so let’s leave operational safety for last. Why make your life difficult at the onset? Instead let’s go for applications where there’s a real economic advantage, such as getting the power up, getting rid of the uncertainties and scheduling your maintenance. There’s so much opportunity there,” says Richard Vilim, Manager of Plant Analysis & Control and Sensors Department at Argonne National Laboratory.

Vilim, who has more than 35-years of research and development experience modeling and simulating power plants, is focused on the cost competitiveness of nuclear while operating alongside renewables, and he is developing AI/ML algorithms that aim to enable autonomous operations using digital twins and automated reasoning methods.

Framework for Autonomous Operation

(Source: Argonne National Laboratory paper; "Explainable and Trustworthy Diagnostics Achievable Through Process-Based Automated Reasoning)

Meticulous and flexible

Today’s computational power works best when set to grind through millions of lines of data in search of anomalies, as when it is monitoring the structural integrity of parts and materials within a plant. It is also adept at reacting in real time to changing circumstances, such as when it is balancing the output from a grid that is supplied by a mix of nuclear, wind, solar and fossil fuels.

Installing sensors in already up and running nuclear power plants was expensive and inefficient, due partly to the high cost of communication by copper wire which connected the sensors. Today, fiber optic cables and wireless transmission are cheap and easy to install, allowing for much larger sensor sets.

Without AI, operators have to give components a wide margin against potential failure, while a large sensor set allows for more pinpoint predictive maintenance. Using the data provided, an operator can anticipate a change before anything fails or underperforms, rather than reacting to a real-time, plant-stopping error, Vilim explains.

“The ability to better detect and diagnose the state of a components’, and a systems’, health can save you a lot of lost down time. You can anticipate when it’s going to fail, and you can schedule maintenance for an advantageous time, like when the plant goes down for refueling. The last thing you want is for the plant to go down when you’re at full power,” he says.

Through secure embedded intelligence with a large enough sensor set, the operator can create a digital twin which can be compared to the physical asset while it is running to spot any anomalies before they become a problem.

At electric power consultancy Kinectrics, researchers found that when utilities perform ultrasonic inspections to map inner and outer surfaces of plant components, such as a pressure tube, they were increasingly coming across interference, or “chatter”, in the signals, which added outage time due to the increased effort needed to analyze the data.

“One attempt was to train a neural network to detect deviations in the expected chatter pattern, which can be used to identify and potentially size indications,” engineer and scientist at Kinectrics, Moe Fadaee said during a webinar on machine learning in nuclear.

Removing the chatter in ultrasonic inspections reduces analysis times and the likelihood of replication and gave greater flexibility in outage times, he said.

Predictive capabilities of AI/ML, when faced with a mixed source grid, can also save money as the machines balance the cost and capability of wind, solar, and nuclear generated power by live processing thousands of pieces of data for 24-hours-a-day.

A computer running the correct modelling system can examine fluctuating supply and demand and the impact of weather (both on demand, depending on air conditioning or heating, and on supply, from solar and wind output) in real time and balance the output of varying generators to find the optimal and cheapest mix, a tough ask for a human operator.

Black box problem

While AI and machine learning offer a number of benefits for the nuclear power industry as it moves toward a new generation of reactors, its range, for the moment, is limited.

A lack of real, operational data from operating nuclear power stations, a varying degree of opinion as to which systems would work best, and the sometimes-mysterious mechanizations within a so-called “intelligent” system, or its “black box” nature, pose potential problems for AI’s use in nuclear.

“There is no universally agreed opinion among researchers for selecting the best artificial intelligence techniques for a specific purpose as intelligent systems developed by various researchers are based on different data set,” independent researcher Siddharth Suman notes in his paper “Artificial intelligence in nuclear industry: Chimera or Solution.”

An interlaboratory work frame or round-robin program to develop the artificial intelligent tool for any specific purpose, based on the same data base, would be crucial in claiming the accuracy and the best technique, he says.

“The black box nature of artificial techniques also poses a serious challenge for its implementation in nuclear industry, as it makes them prone to fooling,” Suman says.

In a 2016 paper published in Nature, “The Black Box Nature of AI”, Davide Castelvecchi says that despite the increased complexity of the data set being examined, neural networks are surprisingly easy to trick with images that, to people, look like random noise. A network might see wiggly lines and classify them as a starfish, for example or, worse still, ill-intentioned hackers could learn to exploit these weaknesses.

These problems make AI and ML especially difficult to regulate, for the moment at least, but may eventually fit into the ASME Nuclear Quality Assurance (NQA-1) Certification Program.

“I think we’re certainly in a place where we can envision a near term future where non-safety systems could incorporate advanced learning to reduce the amount of cognitive effort on the part of the operator, but not with any control of the reactor. We don’t generally let software control reactors – at least not today,” says Kathryn Huff, Acting Assistant Secretary and Principal Deputy Assistant Secretary for the Office of Nuclear Energy.

By Paul Day